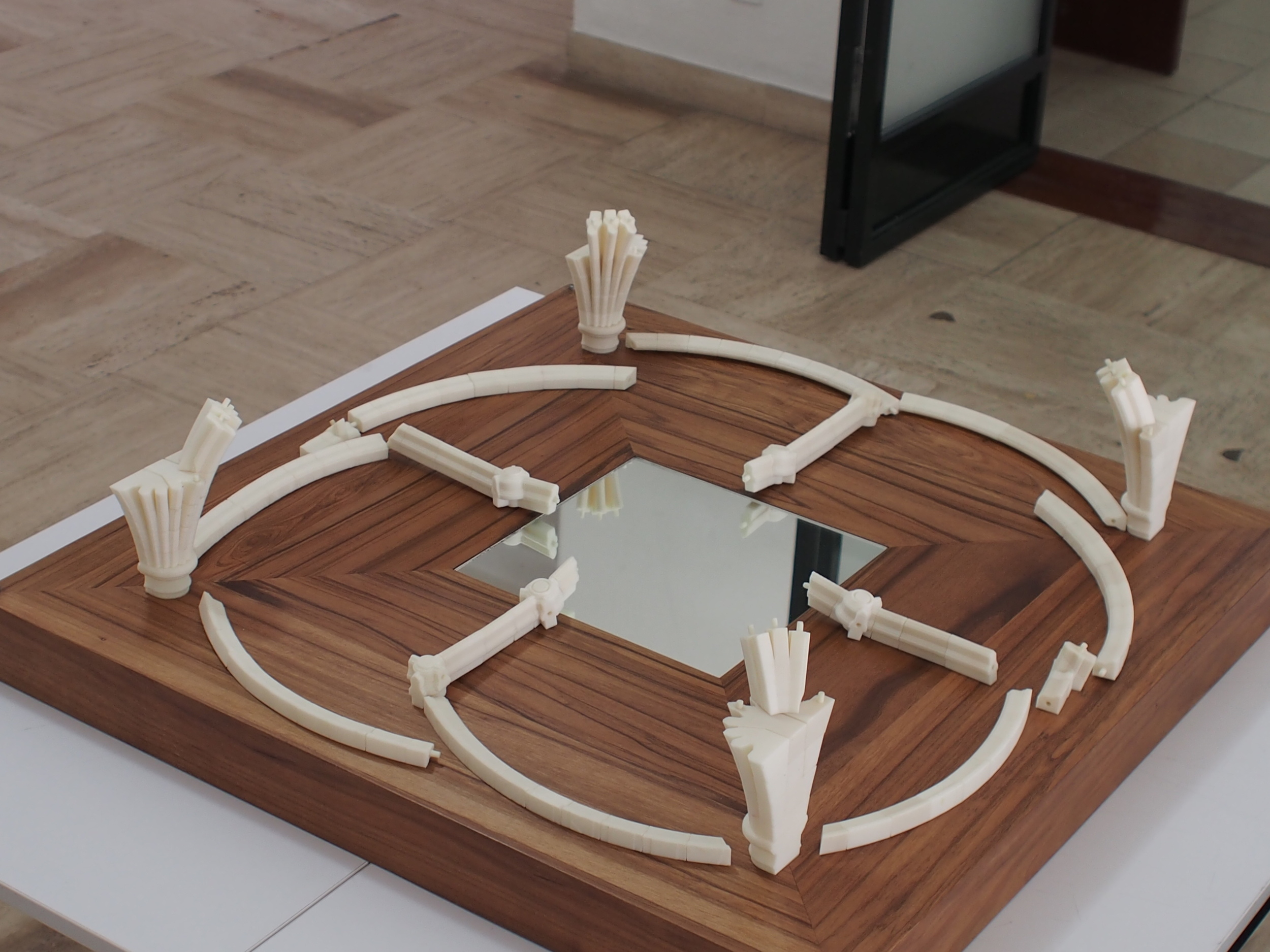

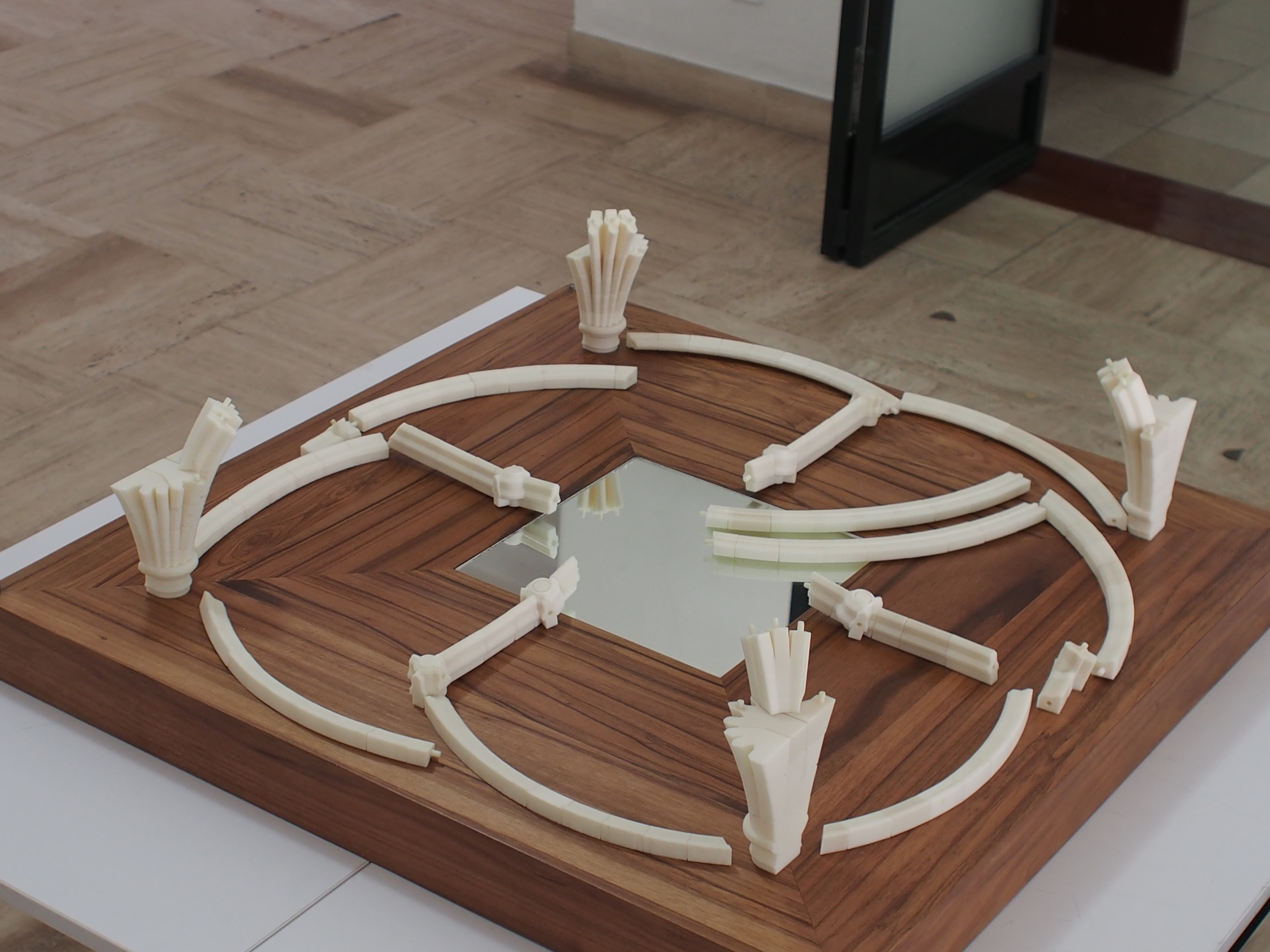

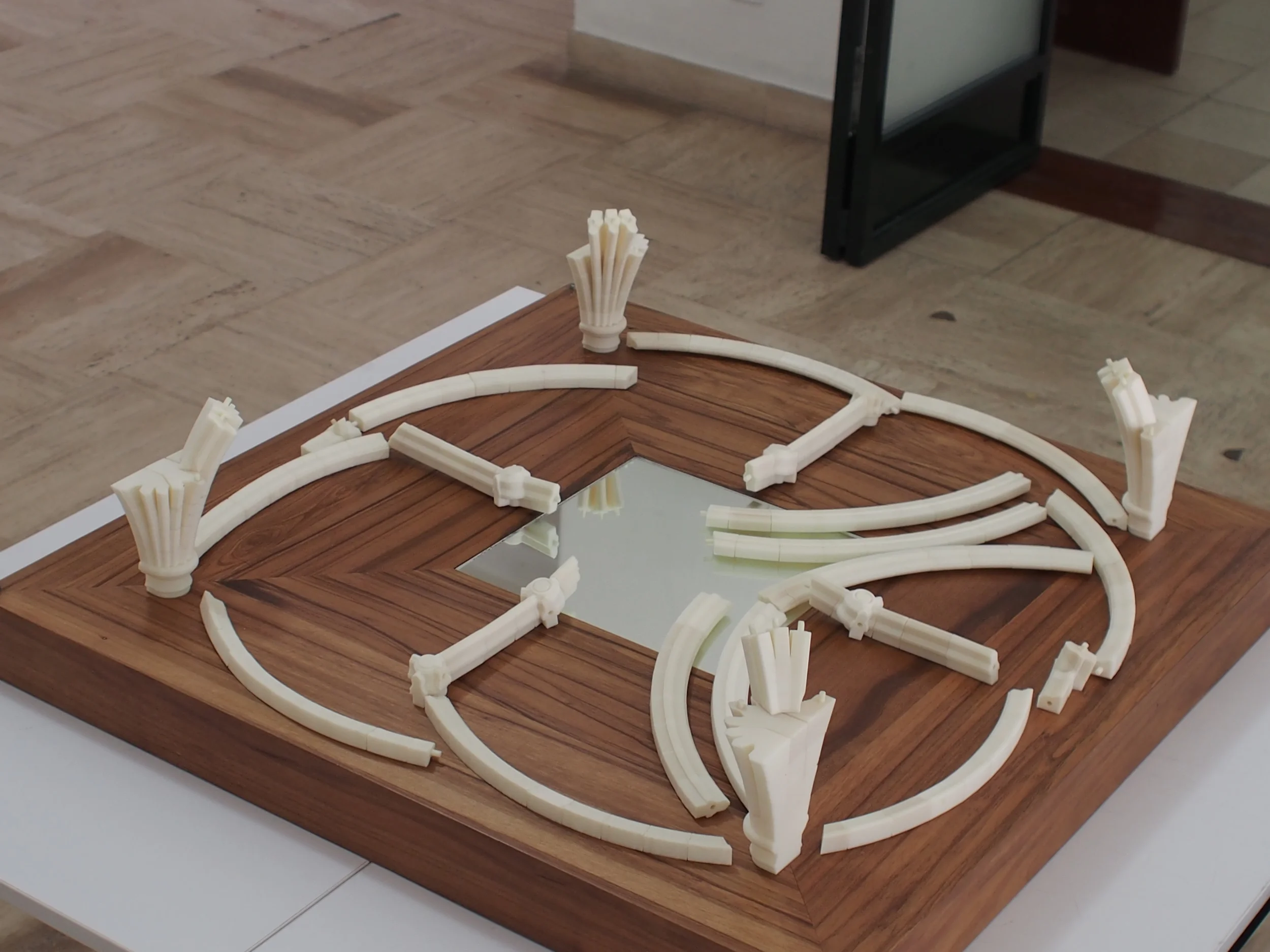

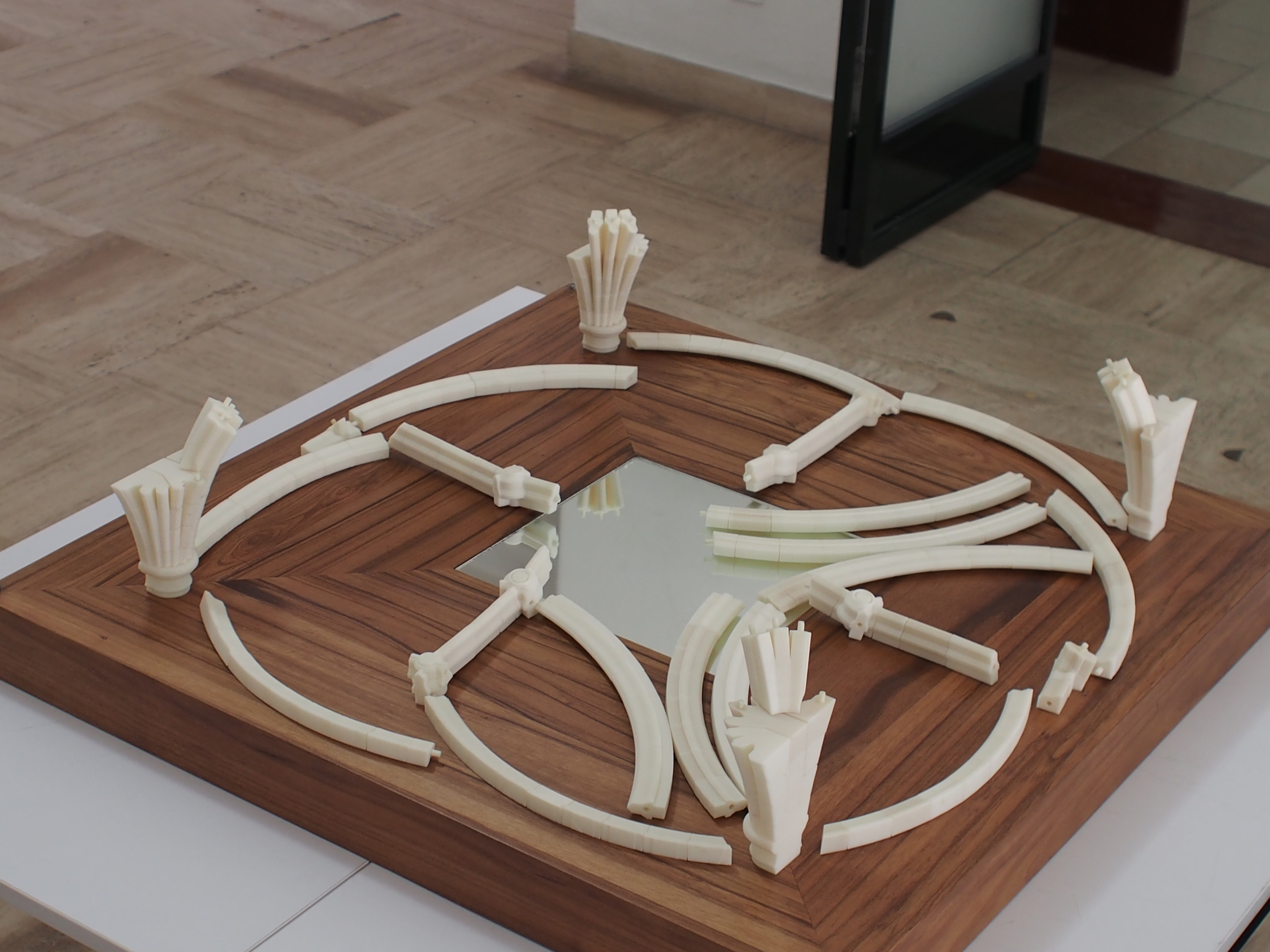

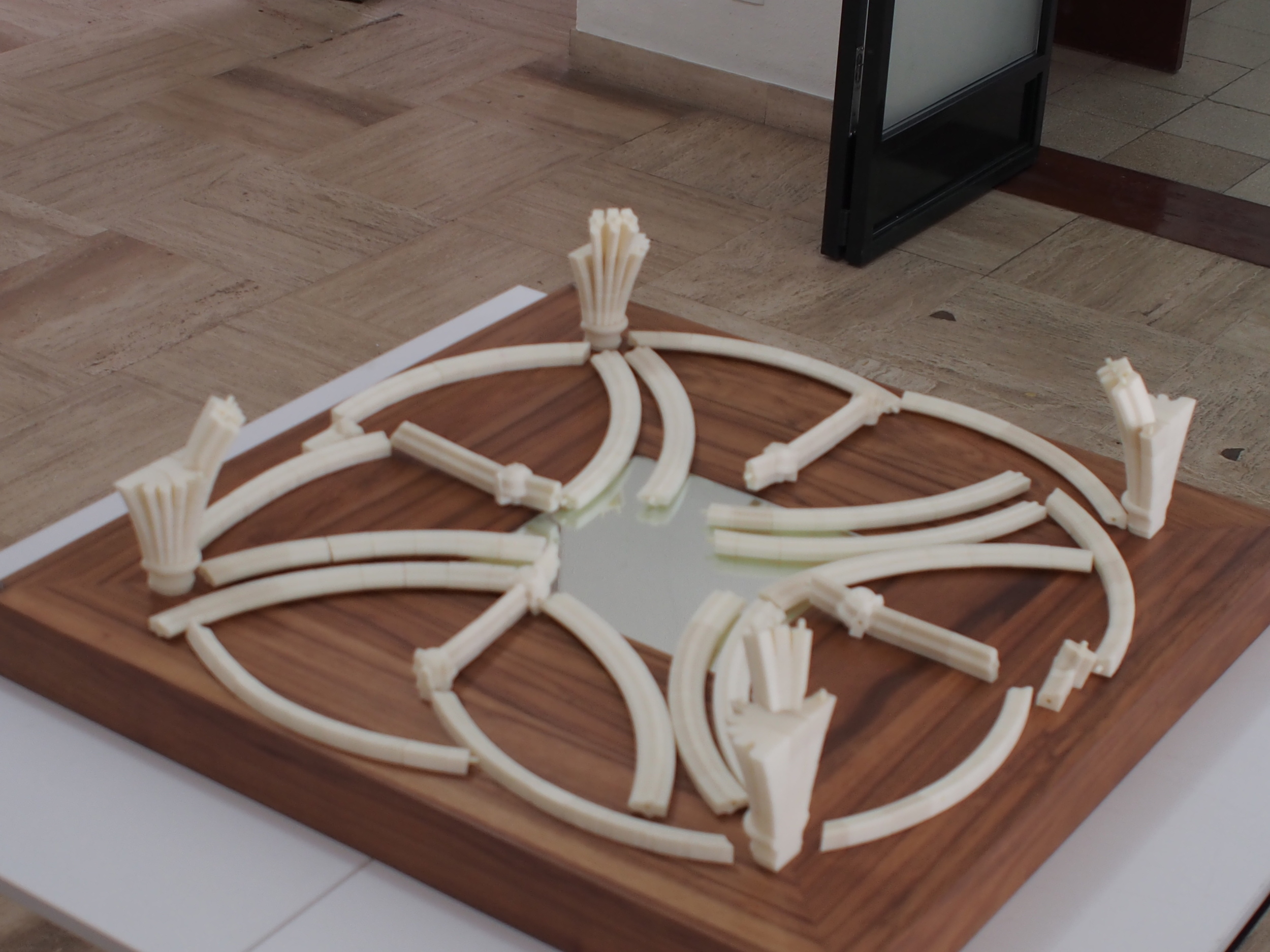

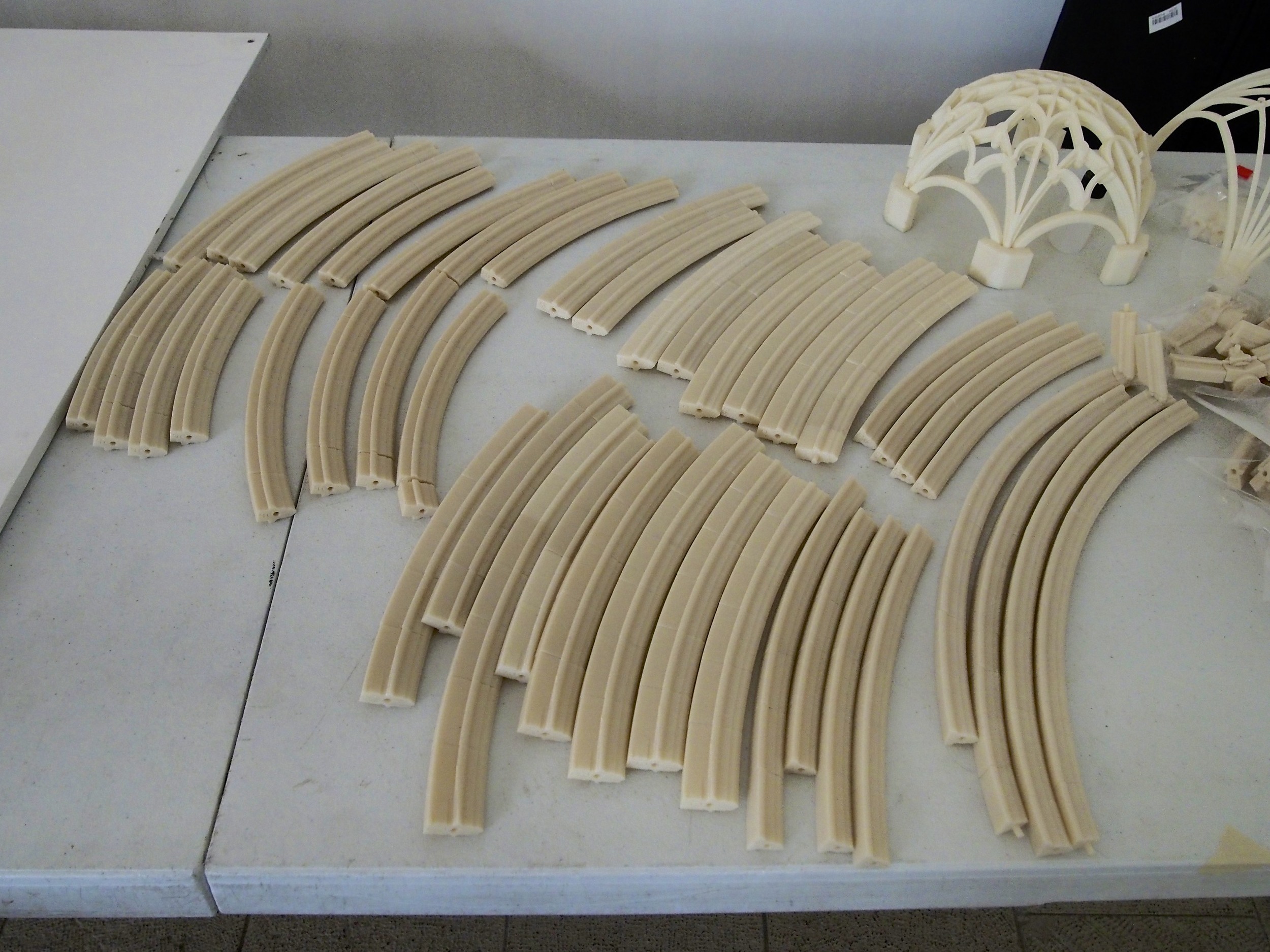

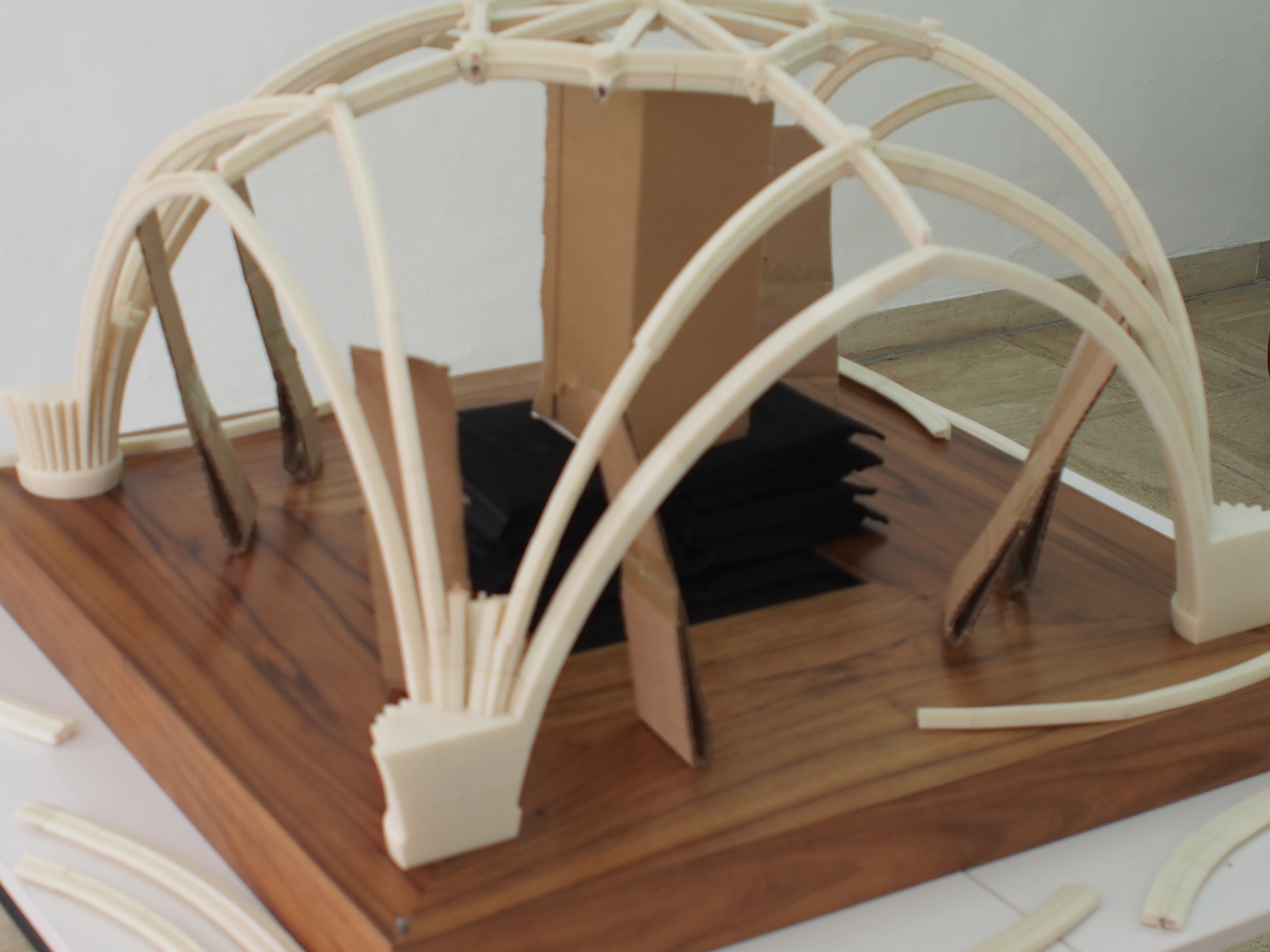

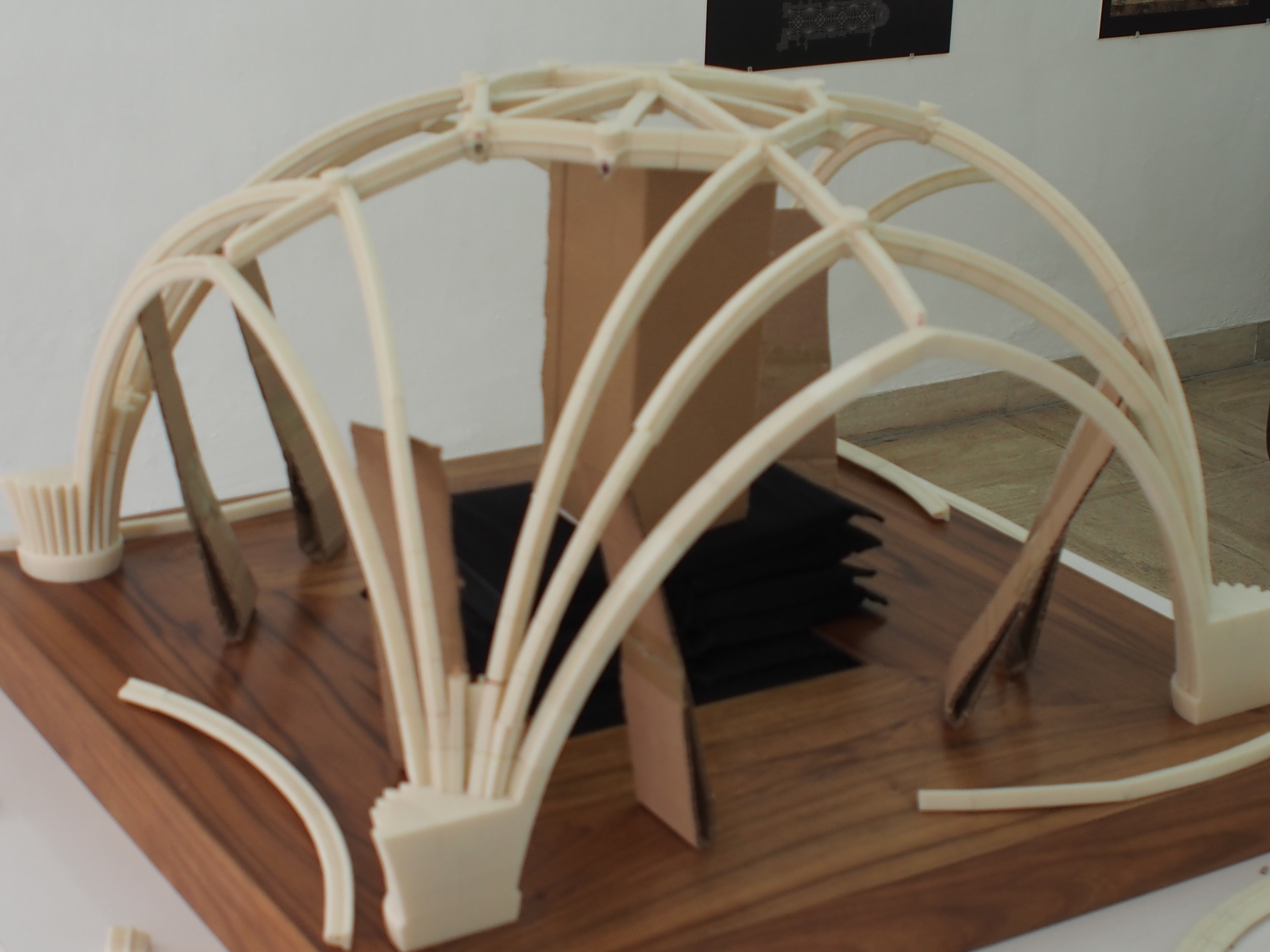

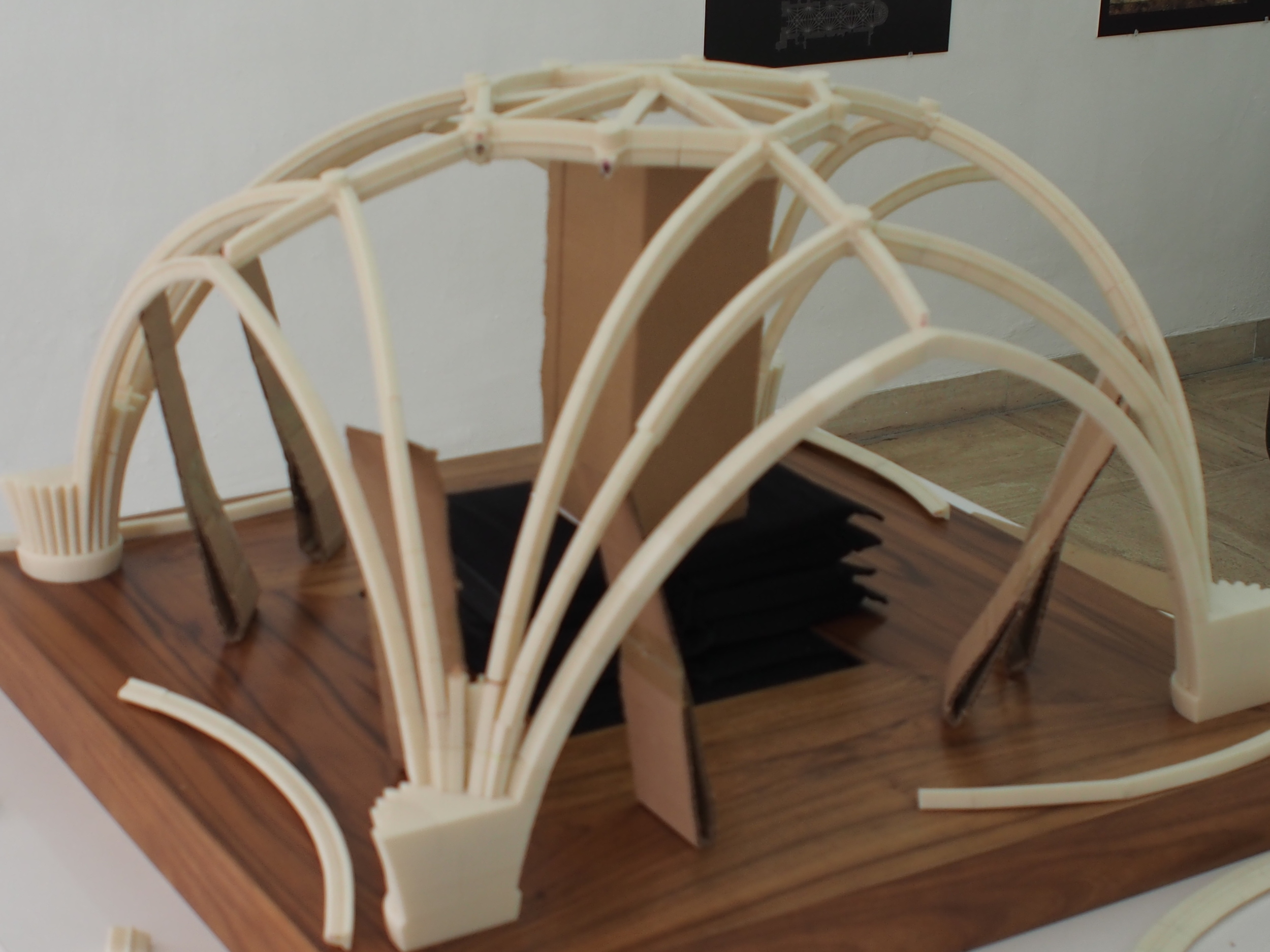

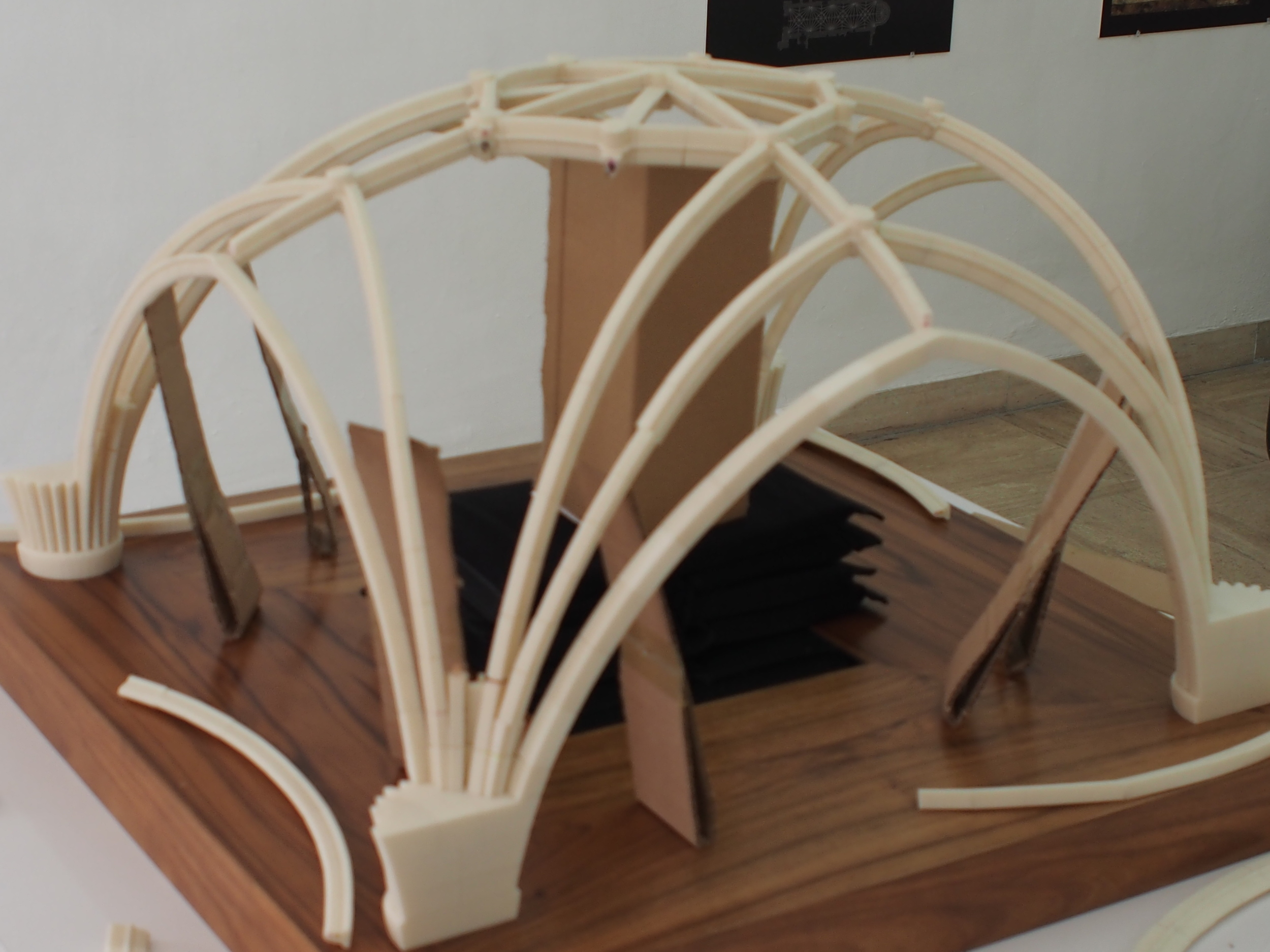

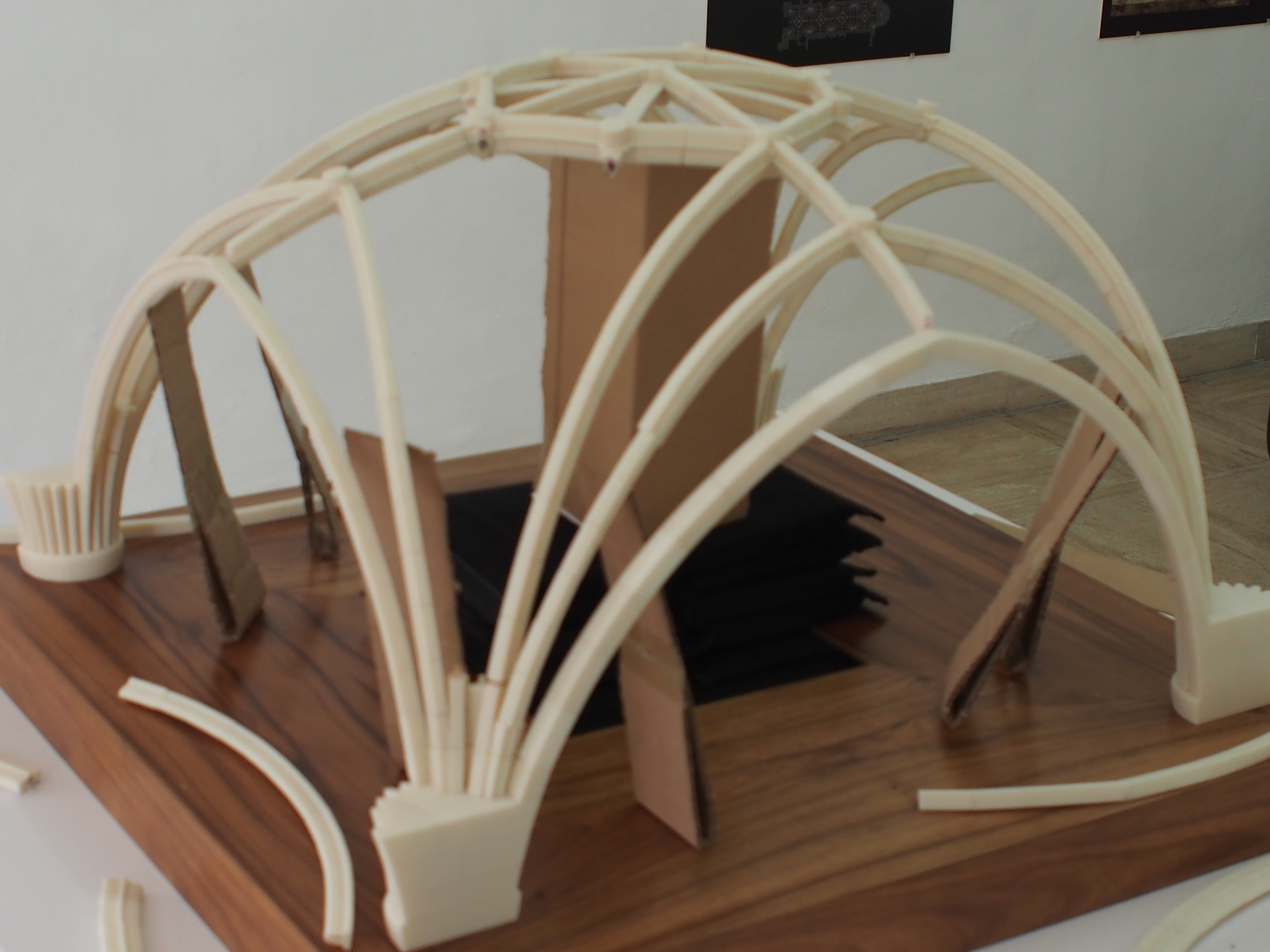

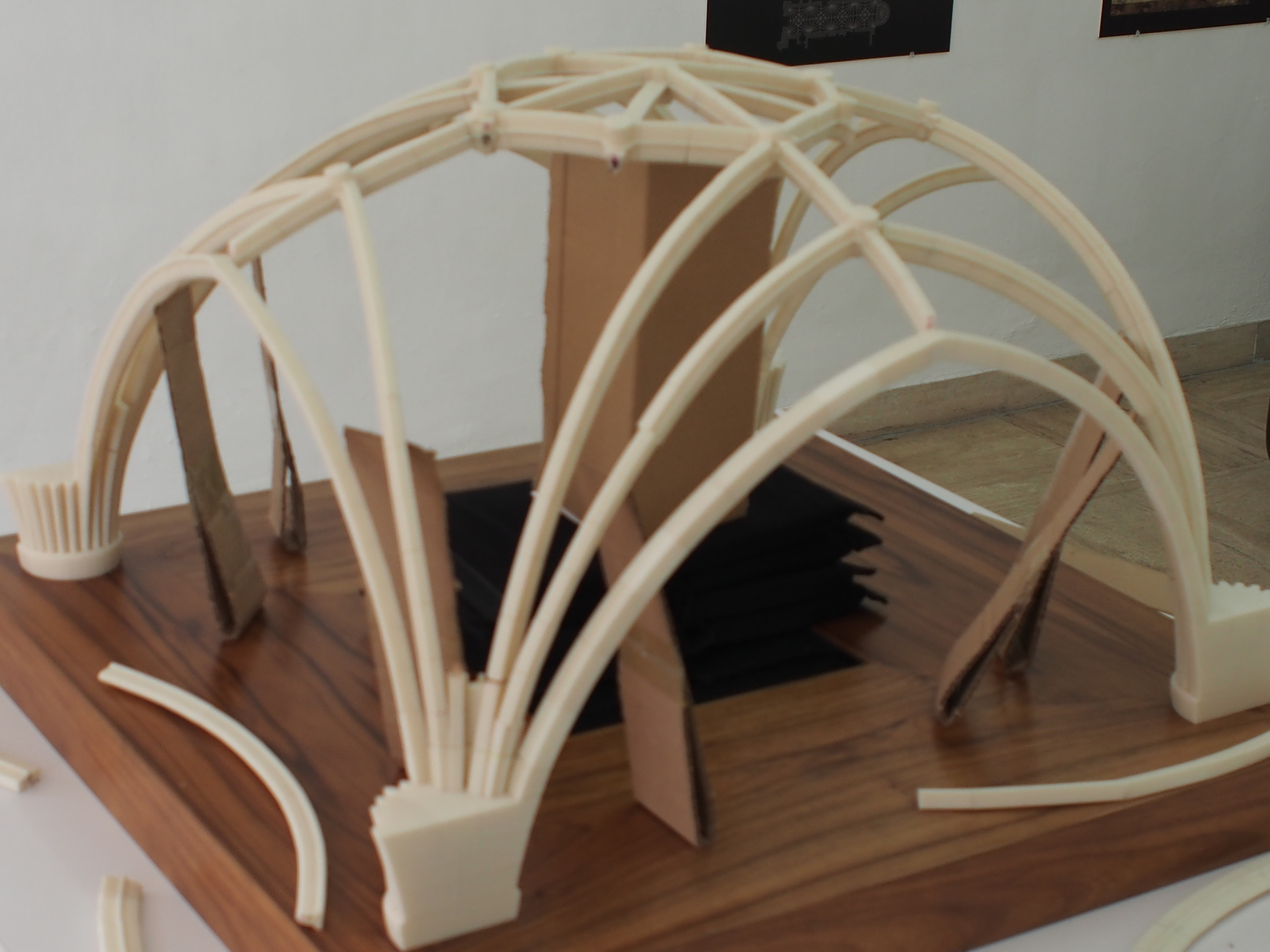

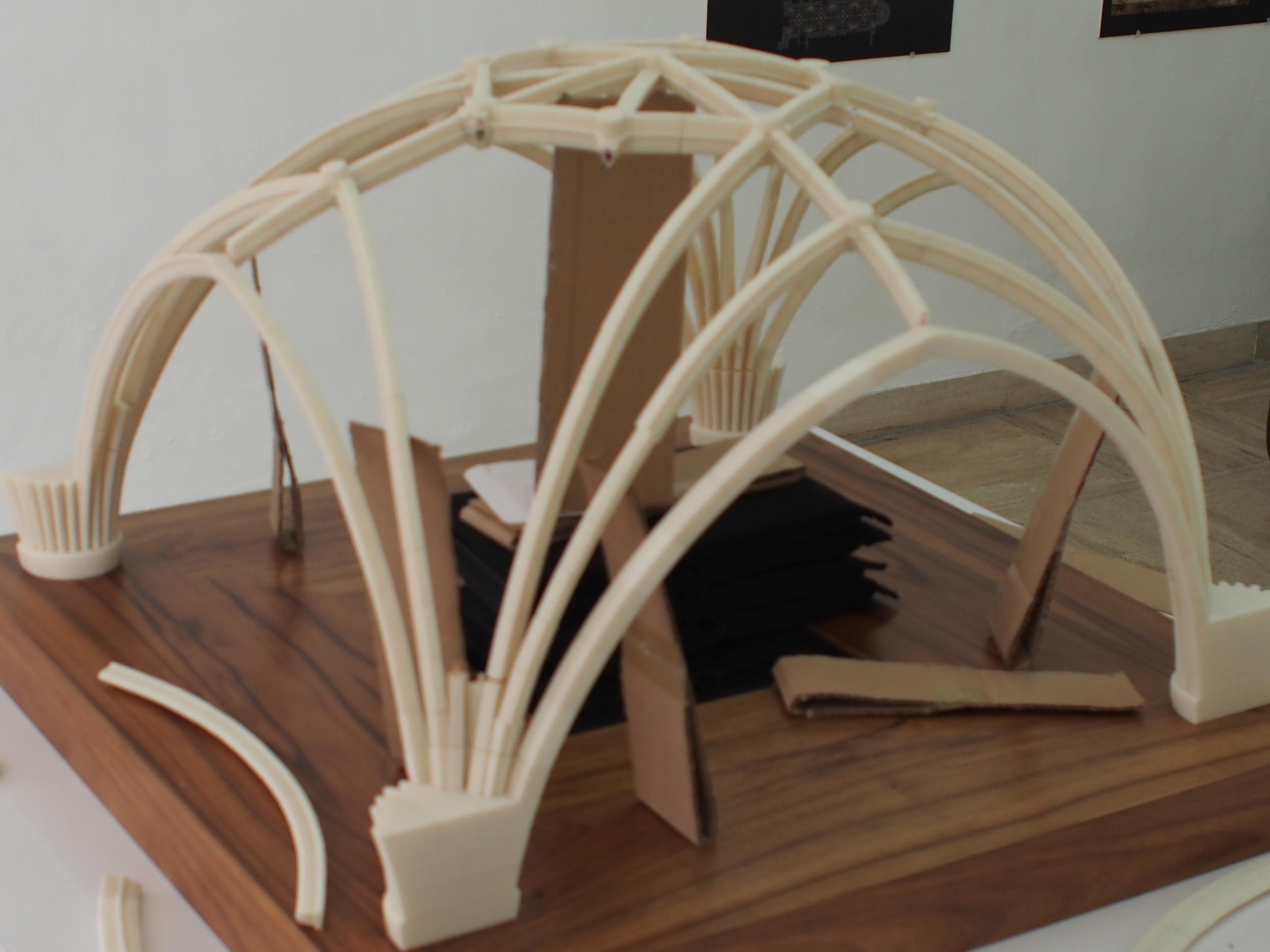

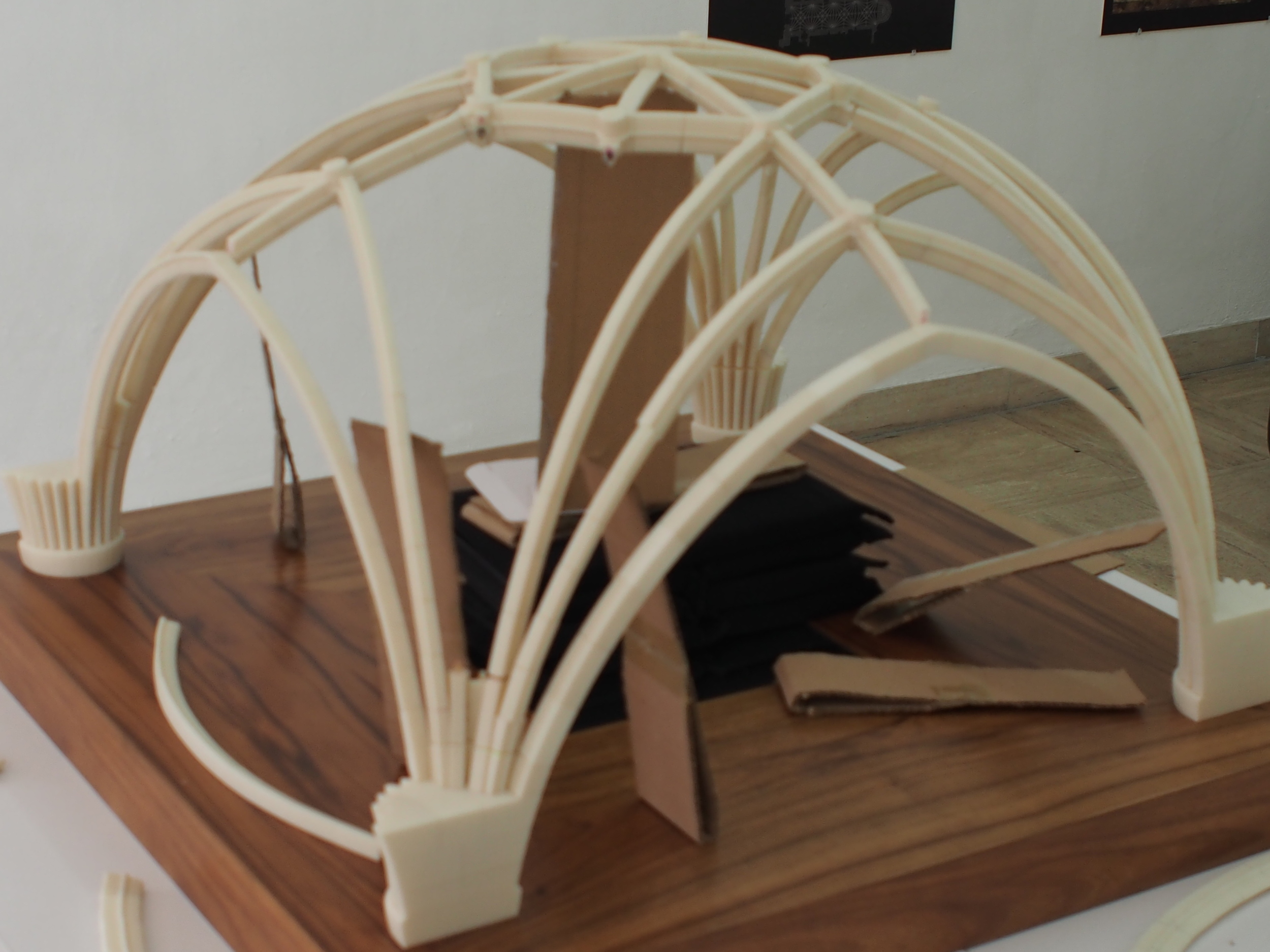

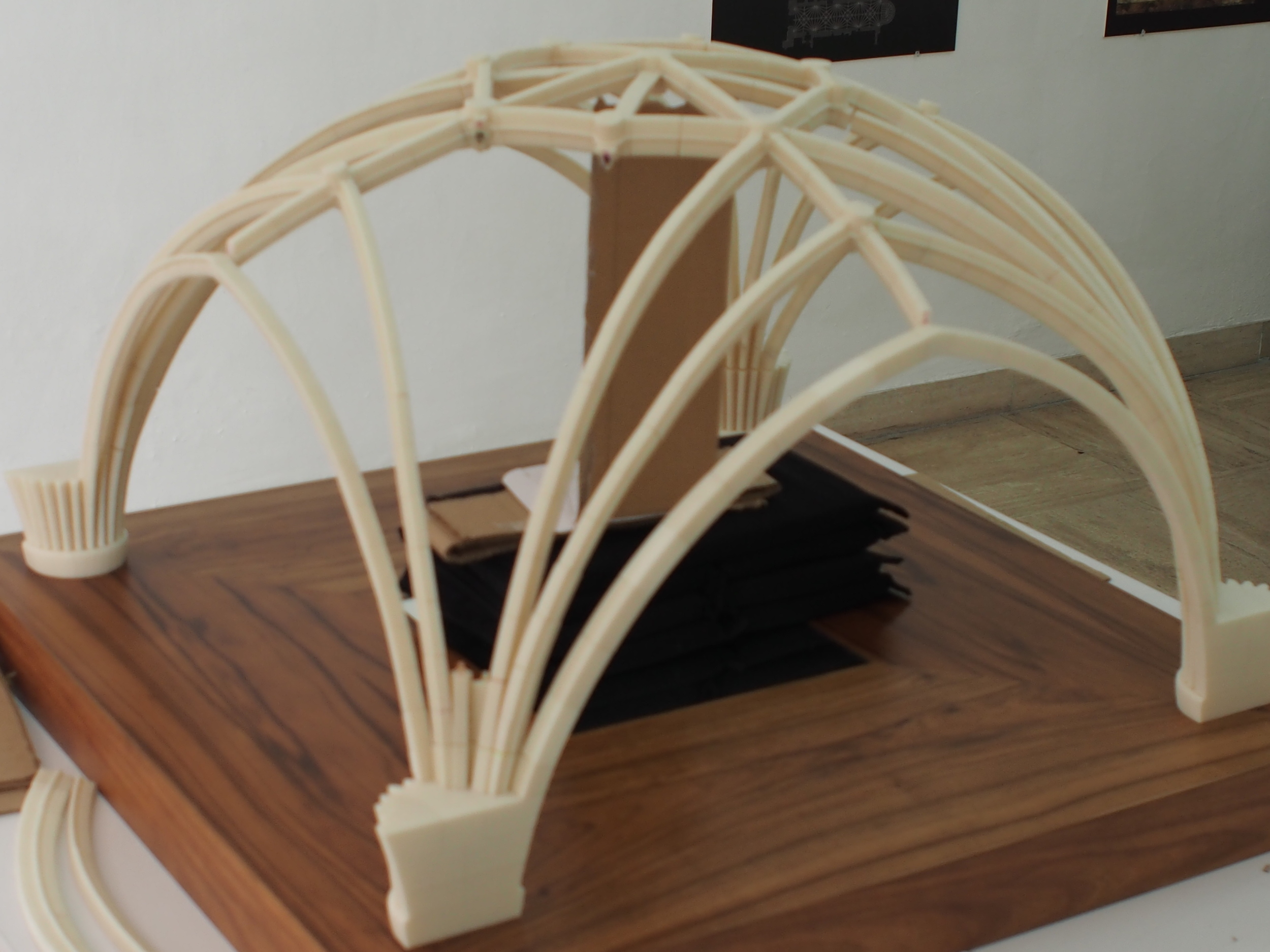

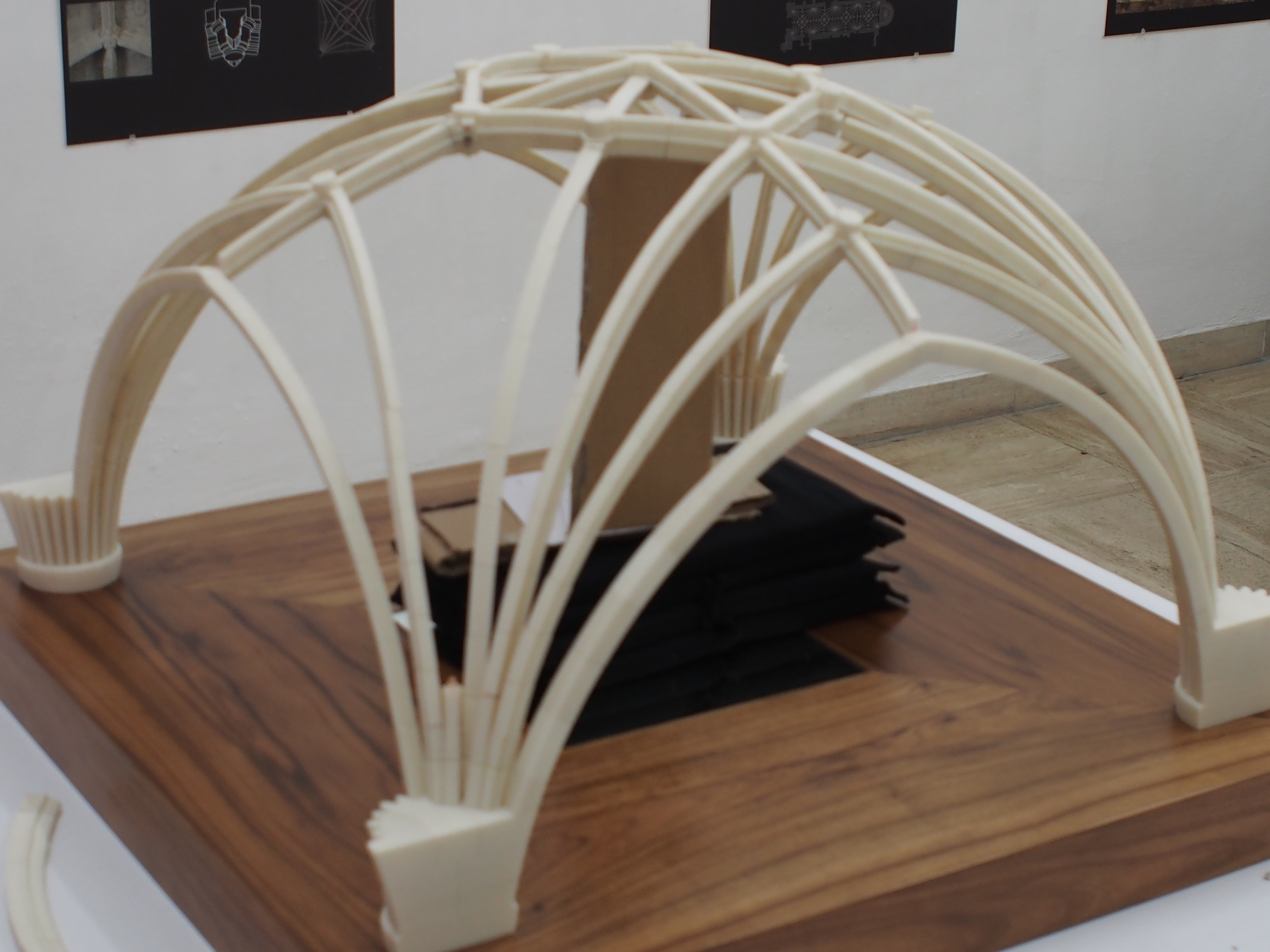

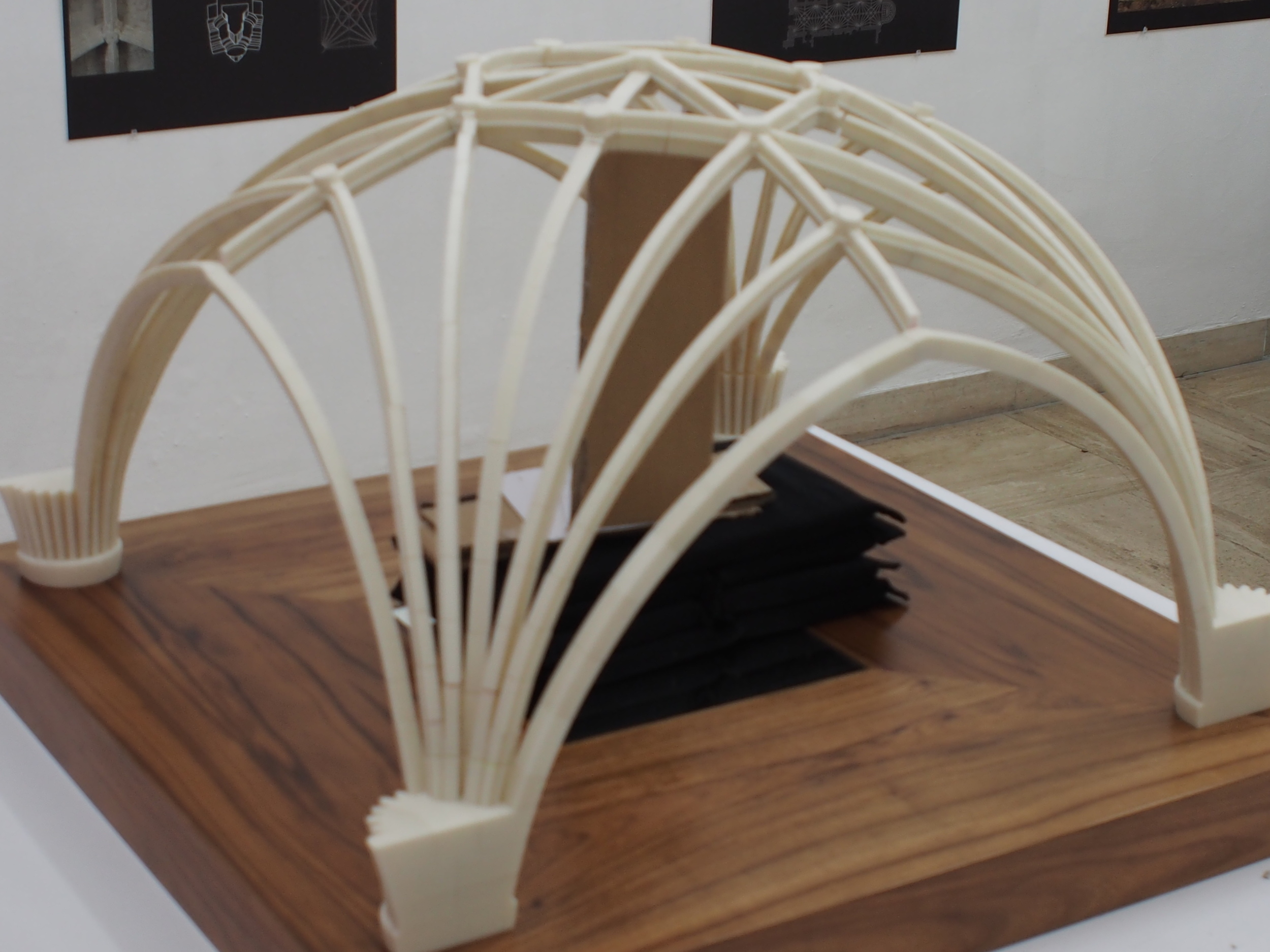

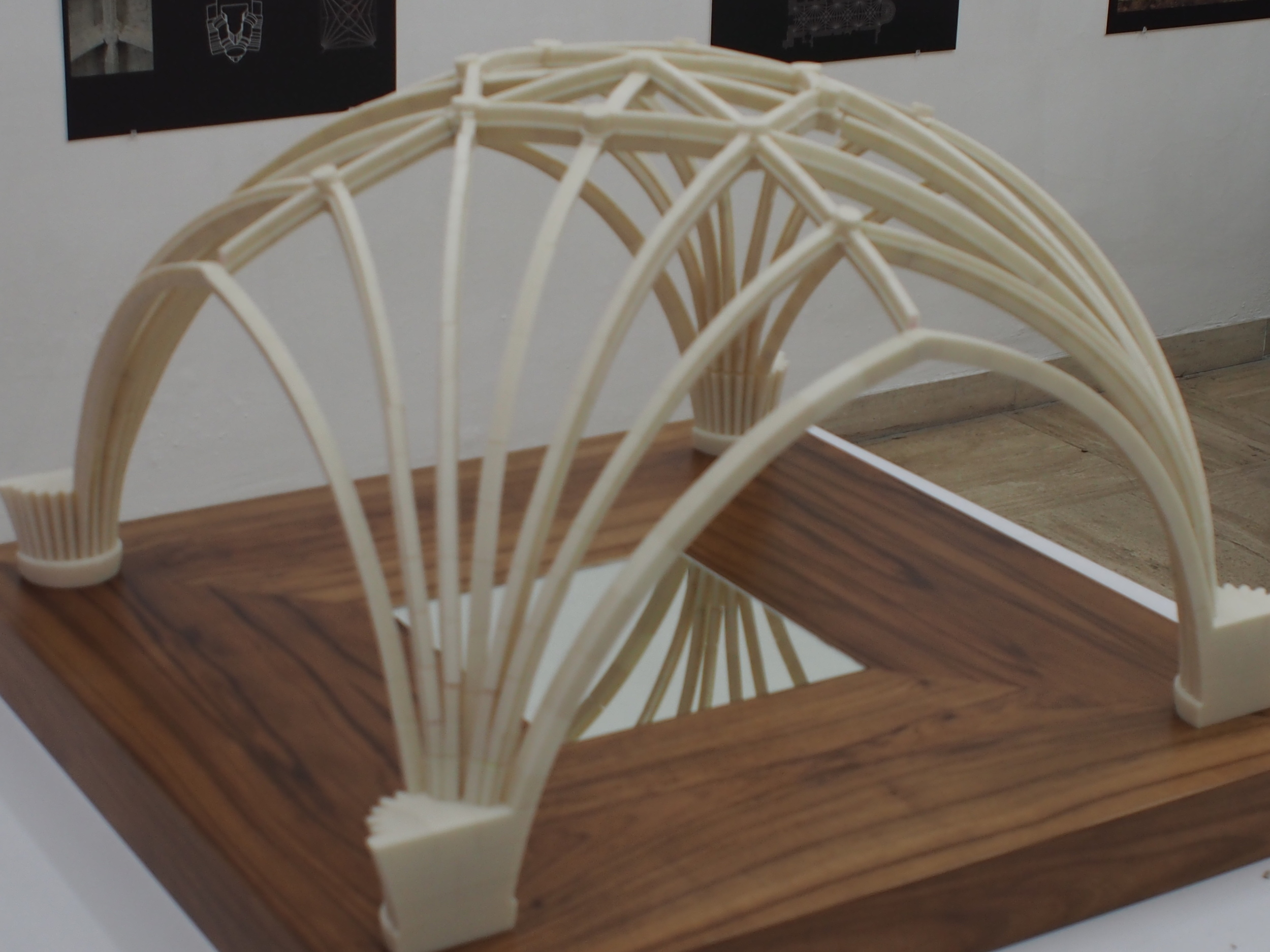

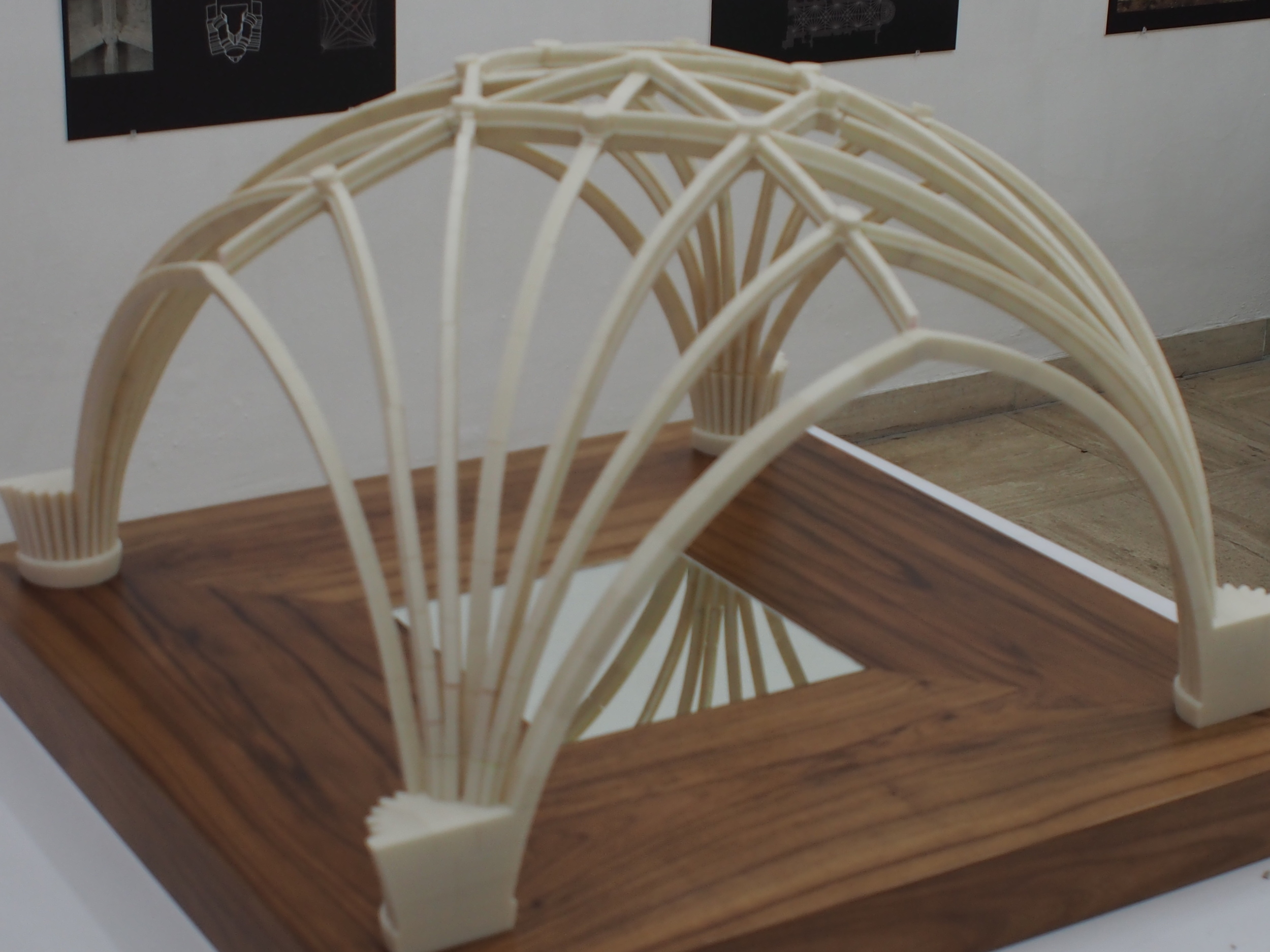

Each one of the vaults' pieces was 3D printed. Hundreds of small pieces make these models, similarly to the real vaults made with stone.

3d PRINTING AND MODELING

This project considered visualization of the vaults as a crucial component of its educative purpose. The research process took advantage of digitals technologies such as digital modeling and 3D printing in order to test an visualize the stereotomic implications of the three vaults. By using 3D printing we were able to develop a series of models that help providing the tangible experience to the viewer and therefore, accomplish the educative goals embedded in this body of work.

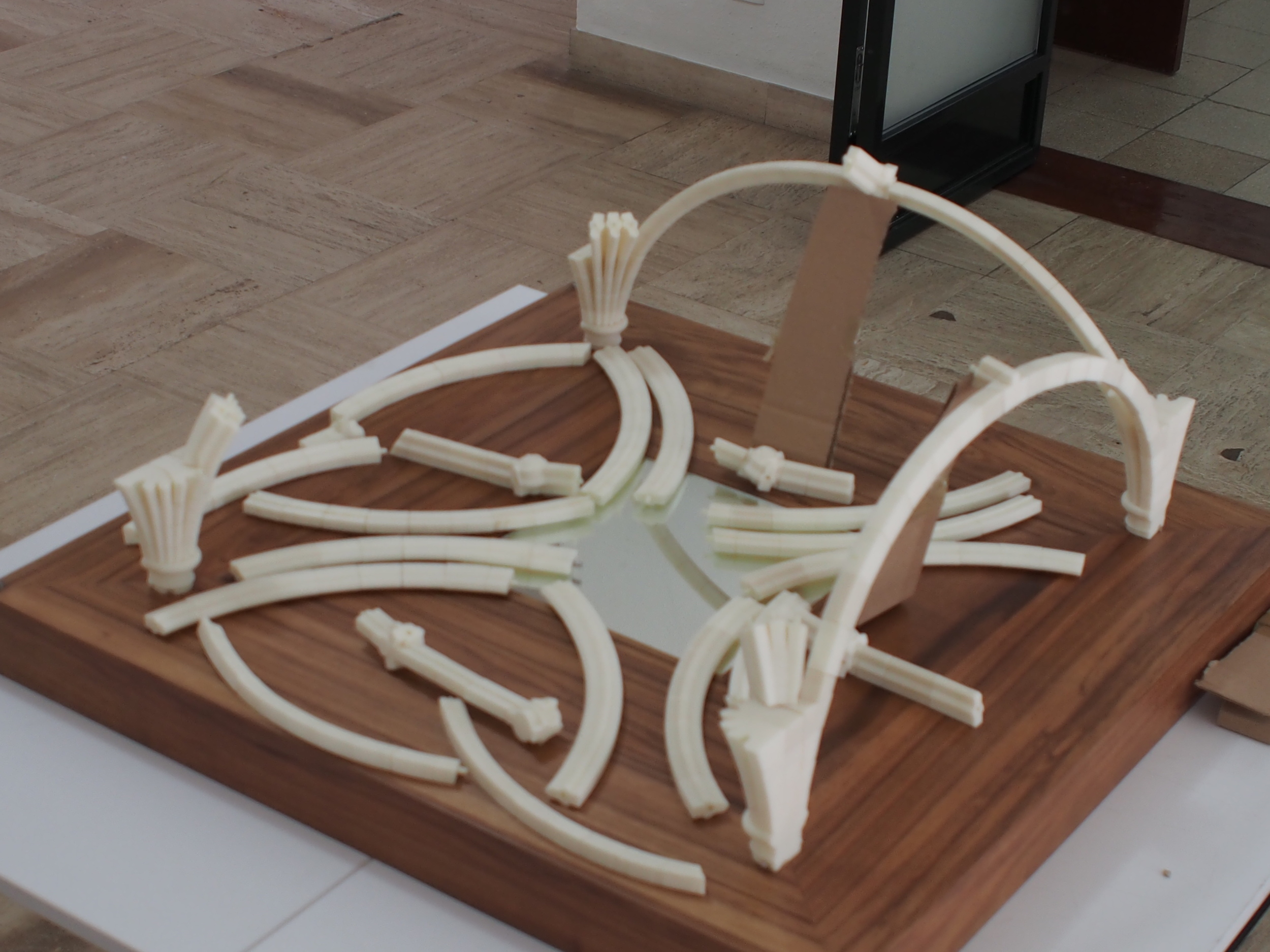

Models assembly

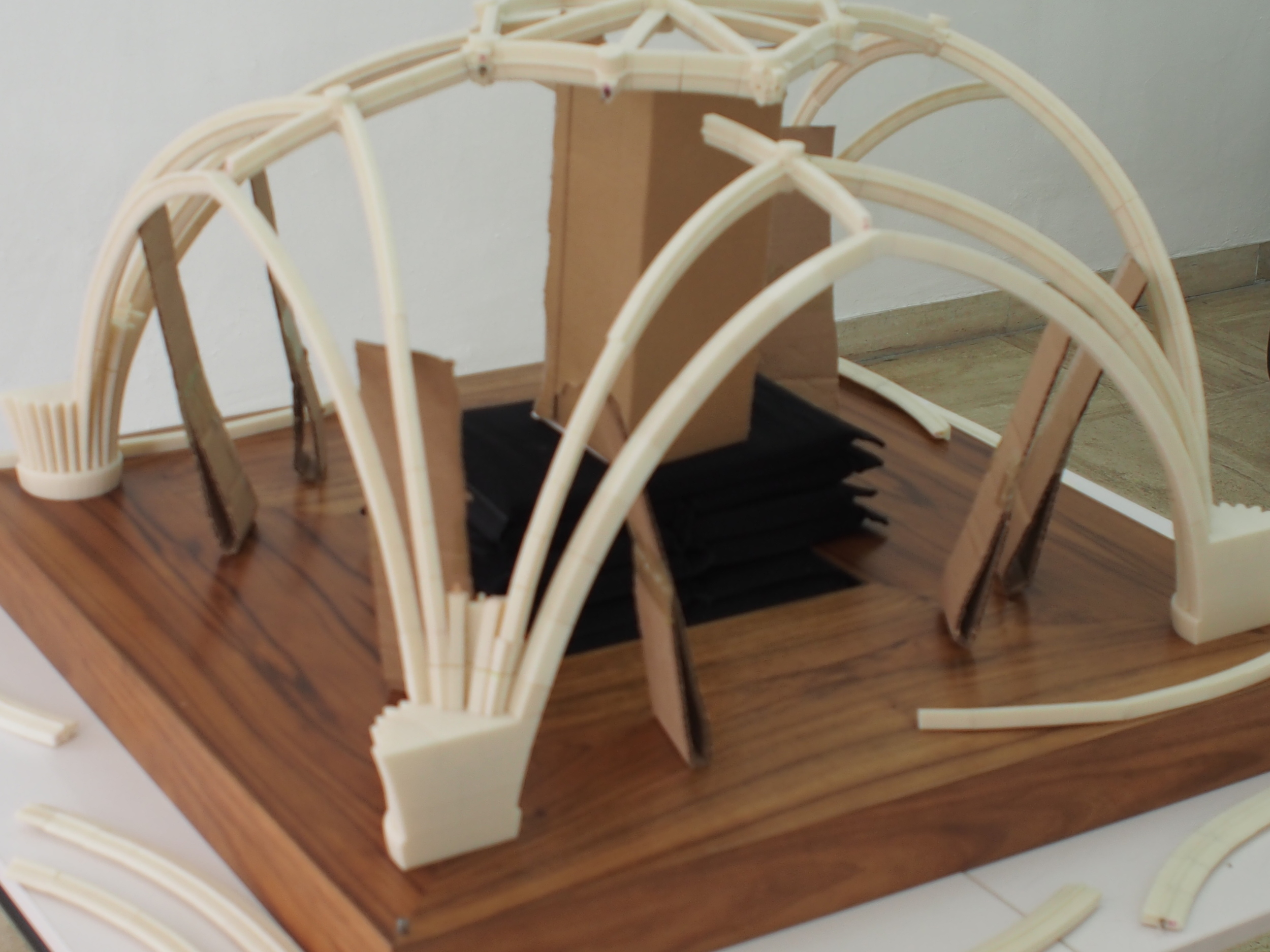

The models mimic the actual vaults made of stone i.e. each individual piece or voussoir was 3D printed. The voussoirs form arches, therefore each of the pieces is assembled as part of an arch. Once each arch is put together they can be placed on the tas-de-charge and connected with the bosses and keystone forming the ribbed vaults. Similarly to the practices of the sixteenth-century master masons, these models help to understand the constructive implications and the structural behavior of the vaults.

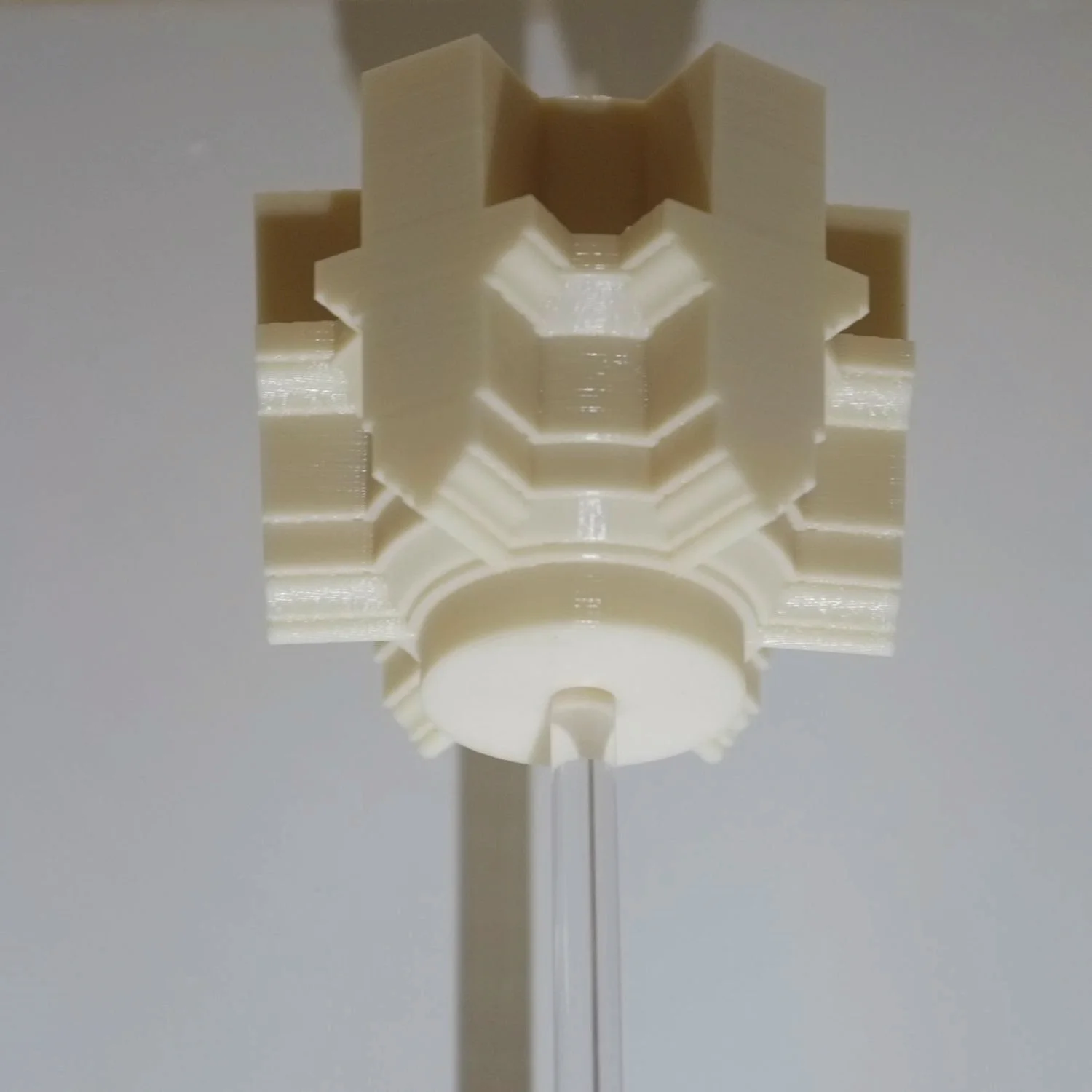

keystone and bosses

The keystone, bosses and tas-de-charges are undoubtedly the most complex pieces within the ribbed vaults. The posed a geometric challenge for the master builders who designed the vaults and presented a complex and meticulous carving process to the masons. This project used 3D printing technology in order to present all the keystones and bosses individually revealing the complexities embeded in each one of them.

Assembling a 3D printed model